plug flow reactor equation

Add a Plug Flow Reactor to the flowsheet and connect the Feed and Product streams remember a shortcut for toggling into and out. Sum x f Ftot for f in F T H Cp r reaction_model x model_param T P dH calc_DeltaH r dP -dpdz dY r dY.

Cstr Vs Pfr Differences And Performance Equations Youtube

A more general expression for PFR if the feed on which conversion is based subscript 0 enters the reactor partially converted.

. Consider j plug flow reactors connected in series and leti23 -fh represent the fraction conversion of the limiting reagent leaving reactors 1 2 3. Gas Limiting and Plug flow of liquid Constant gas phase concentration Height valid for pure gas at high flow rate Relative distance from catalyst particle QA QA ka A Al Arksap Al As Ar 0 l lz l lz dz l B Net input by convection Input by Gas-Liquid Transport Loss by. The fixed-bed laboratory reactor is regarded as an ideal isothermal plug flow reactor.

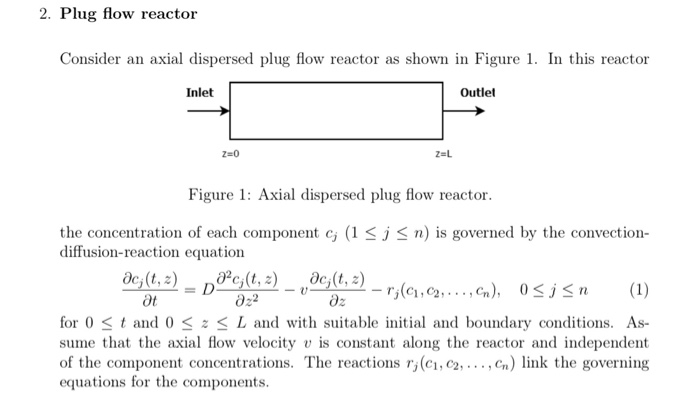

The index i refers to the species i. Diagram of a plug flow reactor showing flow in the z-direction. Plug flow will be achieved if the sublayer thickness is much less than the pipe diameter.

For steady-state operation of a plug flow reactor the basic design equation equation 829 can be written as. F Y 0-2 H Y -2 F. We note however one can approximate the partial differential equation PDE of the unsteady PFR energy balance by replacing the PFR with a number of CSTRs in series.

Substitution for the molar flow rates Fi in terms of conversion gives Equation R137-7. For each of the reactors considered above the appropriate design equation is 827. Beginequation fracdmdt sum_in dotm_in - sum_out dotm_out dotm_wall endequation.

The difference between PFR and MFR is that r A varies in PFR but remains constant in MFR. X is the reactor tube axial position m. Examples of real reactors that.

Both homogeneous gas-phase and heterogenous surface reactions can be accommodated. Dx the differential thickness of fluid plug. Plug Flow Reactor Simulator abstractNote PLUG is a computer program that solves the coupled steady state continuity momentum energy and species balance equations for a plug flow reactor.

There is no doubt that the conversion of this fraction of fluid is lower than that in the plug-flow reactor. Plug Flow Reactor Operating a mass balance on the selected volume V A l and assuming steady-state conditions we obtain ttt0 V dm Qc Qc rdV dt 17 hence cout V cin Q cout Q. Dv 11dA dρ v dz A dz ρdz For a normal pipe dA 0 and for a liquid dz dρ 0 dz Therefore.

The total mass of the reactors contents changes as a result of flow through the reactors inlets and outlets and production of homogeneous phase species on the reactor walls. 5 CHE 416 CHEMICAL REACTION ENGINEERING II Eqn3-3 allows the determination of reactor size for a given feed rate and required conversion in a PFR. The reactor model consists of the continuity equations for 1 N 2 CO NO O 2 CO 2 N 2 O and NO 2 in the gas phase 2 surface species adsorbed on the noble metal surface 3a surface species adsorbed on the ceria surface 3b species in the ceria sub-layer 4 CO 2 adsorbed on the γ.

The reactor may be either isothermal or adiabatic or may have a. D is the tube diameter m. Append dP return dY define initial.

This equation can be integrated along the length of the reactor to yield relationships between reactor resident time and concentration or conversion. X concentration of microorganisms at any point in contact reactor Xo influent concentration of microorganisms 106 E. Coli100 ml k d 5 hr-1 r c rate of chlorine decay from microorganism Cl-demand -k c X k c 10-5 mg-chlorineL100mL-1hr-1 2 rate expressions 2 constituents 2 coupled mass balances find.

The equations governing the behavior of the plug flow reactor are simplified versions of the general relations for conservation of mass energy and momentum4 They can be derived most easily by writing balances over a differential slice in the flow direction x. Dv 0 vv dz 0. The Langmuir-Hinshelwood equation you may or may not remember from CENG 390 is the form used for heterogeneous catalysis when you must worry about products or inerts using up active sites on the solid catalyst.

Return-r 0 H_A-r 1 H_B r 2 H_C define the plug flow reactor model def plug_flow_reactor_gas z Y dpdz model_param reaction_model. Chemical Reaction Engineering CRE deals with the design of Chemical Reactors to produce chemicals. 62 which is the basic form of the design equation for a plug-flow reactor V is the reactor volume G is the total mass flow through the reactor Cao is the concentration of A at inlet in moles per unit mass of feed Xa is the fractional conversion of A.

A t is the tube transverse cross sectional area m2. Derivation of the design equation for a plug flow reactor with second order kineticsPresented by Professor Alan Hall University of Huddersfield. F i x is the molar flow rate of species i at the position x mols.

Made by faculty at the Universit. 531 one can see that the fraction of fluid particles with residence time shorter than t over the total fluid is F t 1 e1 0632. The design of Chemical Reactors is based on a few.

Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor. Sum P Y -1 Ftot F. In fact real reactors can be modeled as networks or combinations of multiple plug-flow and stirred-tank reactors Towler and Sinnott 2013.

One then simply solves the coupled ODEs using Polymath or MATLAB. ρCWii For a liquid dρ 0 dz dvρA dv dA dρ ρρAvAv0 dz dz dz dz Rearrange. DV area dz Mass flow rate is constant vAρconst.

Sizing A Plug Flow Reactor Pfr Youtube

Computational Scheme For A Plug Flow Reactor Defining The Function Download Scientific Diagram

Plug Flow Reactor With First Order Kinetics Performance Equation Youtube

Introduction To Energy Balances For Plug Flow Reactors Youtube

Design Equation Of Plug Flow Reactor Chemical Reaction Engineering Lecture 08 Hindi And Urdu Youtube

Matlab In Chemical Engineering At Cmu

Mole Balance On A Plug Flow Reactor Youtube

2 Plug Flow Reactor Ler An Axial Dispersed Plug Flow Chegg Com

Plug Flow Reactor Overview Youtube

Solved 4 20 Points Consider A Plug Flow Reactor As Chegg Com

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Plug Flow Reactor With Second Order Kinetics Design Equation Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

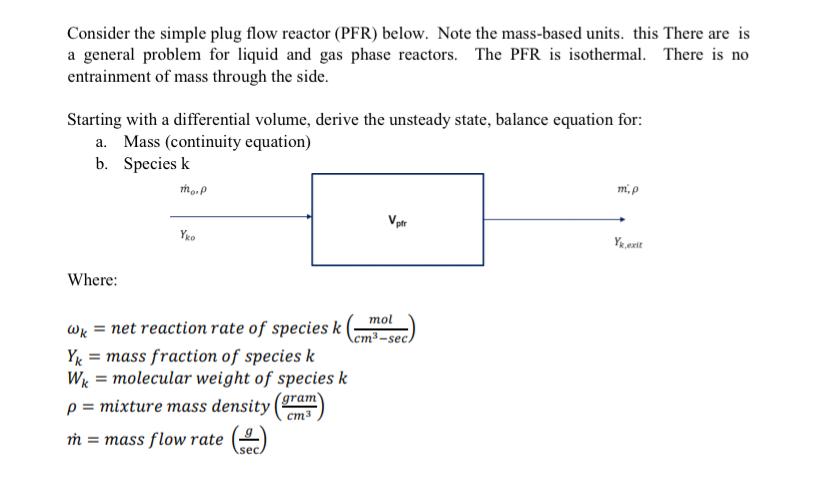

Solved Consider The Simple Plug Flow Reactor Pfr Below Chegg Com

Plug Flow Reactor Design Equation Youtube

Introduction To Energy Balances For Plug Flow Reactors Youtube